Grinding Wheel Cutting Speed . Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Abrasives — grits and grains. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Grinding wheels and other bonded abrasives have two major components: Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. If you want to know the. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,.

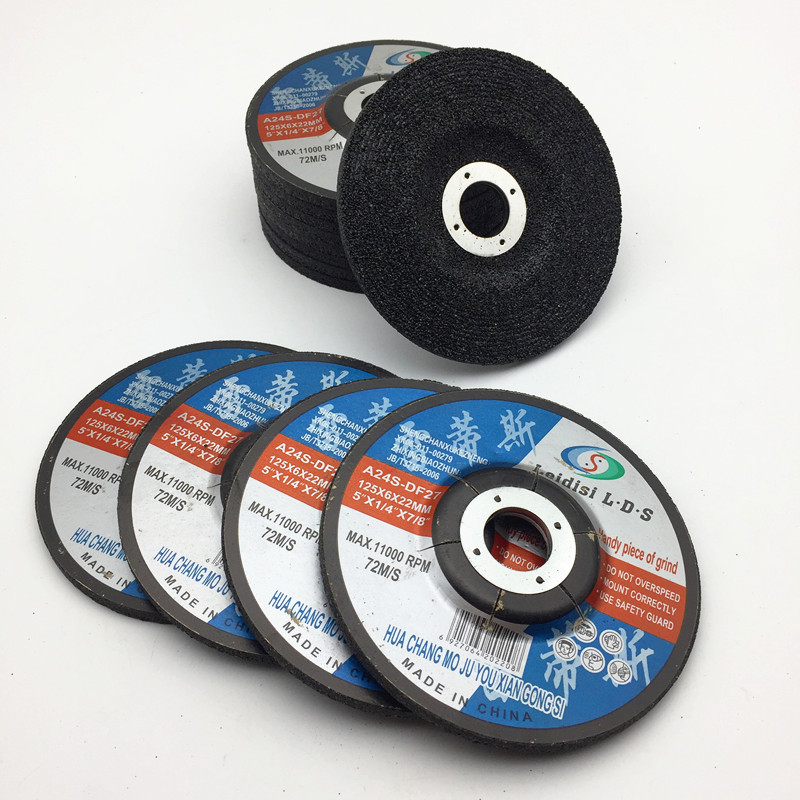

from www.ebay.com

Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. Grinding wheels and other bonded abrasives have two major components: If you want to know the. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Abrasives — grits and grains. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required.

125mm 5" Grinding Disc Wheel 6mm Angle Grinder Polish Cutting Flap

Grinding Wheel Cutting Speed Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Abrasives — grits and grains. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. If you want to know the. Grinding wheels and other bonded abrasives have two major components: The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required.

From www.mhe4u.com

Abrasive Wheels (Cutting and Grinding) MHE Training in all of the UK Grinding Wheel Cutting Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Abrasives — grits and grains. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed. Grinding Wheel Cutting Speed.

From www.lowes.com

DEWALT Aluminum Oxide 4.5in 24Grit Cutting/Grinding Wheel at Grinding Wheel Cutting Speed Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Grinding,. Grinding Wheel Cutting Speed.

From www.lazada.com.ph

BOSCH Grinding Wheel Expert For Metal 4" Inch Grinding Disc Wheel For Grinding Wheel Cutting Speed Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. If you want to know the. Grinding wheels and other bonded abrasives have two major components: Wheel speed determines what. Grinding Wheel Cutting Speed.

From www.aliexpress.com

Angle Grinder 220v 670w Speed Control Cutting Polishing Machine GWS6 Grinding Wheel Cutting Speed Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for. Grinding Wheel Cutting Speed.

From www.crystalalloys.com

GRINDING WHEELS/CUTTING WHEELS Crystal Foundary Grinding Wheel Cutting Speed Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Abrasives — grits and grains. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm). Grinding Wheel Cutting Speed.

From www.bossabrasive.com

Cutting / Grinding wheel Grinding Wheel Cutting Speed Abrasives — grits and grains. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. If you want to know the. Wheel speed determines what bond. Grinding Wheel Cutting Speed.

From usamerica.shop

Wood Angle Grinder wheel blade Disc Grinding, Carving & Cutting Grinding Wheel Cutting Speed If you want to know the. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. Abrasives — grits and grains. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Grinding wheels and other bonded abrasives have two major components: Common. Grinding Wheel Cutting Speed.

From dcygmj.en.made-in-china.com

High Performance 9inch Cutting Disc Grinder Wheel Cutting Abrasives Grinding Wheel Cutting Speed The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Abrasives — grits and grains. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. If you want to know the. Grinding wheels and other bonded abrasives have two major. Grinding Wheel Cutting Speed.

From www.tilechoice.co.uk

DCW888 115MM Diamond Cutting / Grinding Wheel Tile Choice Grinding Wheel Cutting Speed The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the. Grinding Wheel Cutting Speed.

From www.indiamart.com

Black Metal 6 Inch Grinding Wheel For surface grinding machine Grinding Wheel Cutting Speed Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. If you want to know the. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for. Grinding Wheel Cutting Speed.

From www.tradeindia.com

100125mm Cutting And Grinding Wheel Making Machine at Best Price in Grinding Wheel Cutting Speed If you want to know the. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead. Grinding Wheel Cutting Speed.

From www.ebay.com

125mm 5" Grinding Disc Wheel 6mm Angle Grinder Polish Cutting Flap Grinding Wheel Cutting Speed Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Grinding,. Grinding Wheel Cutting Speed.

From www.walmart.com

Uxcell 4 Inch Flap Pad 72 Page Grinding Wheel for Angle Grinder 320 Grinding Wheel Cutting Speed The spee d octor our “smart” feed and speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for milling,. If you want to know the. Grinding wheels and other bonded abrasives have two major components: Abrasives — grits and grains. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips. Grinding Wheel Cutting Speed.

From www.indiamart.com

PRETEC Grinding & Cutting Wheels 41/2 inch Set ,Angle Grinder Wheel Grinding Wheel Cutting Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Abrasives — grits and grains. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. If you want to know the. Wheel speed determines what bond type is most suited for the required speed. Grinding Wheel Cutting Speed.

From shopee.com.my

POSENPRO 125mm Angle Grinder Wheel Cutting Disc 5Inch Metal Stainless Grinding Wheel Cutting Speed Abrasives — grits and grains. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. Grinding wheels and other bonded. Grinding Wheel Cutting Speed.

From www.walmart.com

105mm x 1mm Stainless Steel Cut Off Disc Cutting Wheel for Angle Grinding Wheel Cutting Speed Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety. Wheel speed determines what bond type is. Grinding Wheel Cutting Speed.

From www.diamondlaps.com

4.5 Inch 115 Mm Sintered Turbine Segmented Diamond Grinding Wheels For Grinding Wheel Cutting Speed Speeds for grinding are measured as peripheral wheel speed in surface feet per minute (sfpm) instead of rpm of the wheel. Common cutting wheel diameters range from 2 to 4 inches for die grinders, 4 to 9 inches for angle grinders, and 12 to 20 inches for chop,. The spee d octor our “smart” feed and speeds wizard will recommend. Grinding Wheel Cutting Speed.

From www.sakabrasives.com

Thread and Gear grinding Sak Abrasives Grinding Wheel Cutting Speed Abrasives — grits and grains. Grinding, or abrasive machining, is the process of removing metal in the form of minute chips by. Wheel speed determines what bond type is most suited for the required speed or if a special high speed bond might be required. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety.. Grinding Wheel Cutting Speed.